Google Buttonwall

Permanent interactive installation

Hardware custom designed and built to run Deep Locals Anypixels.js at Google Headquarters Brazil. Due internal reasons, I was asked to redesign all the hardware (of which I built 100+ controller boards manually), Vitaliano Palmieri did the Firmware, adapted Anypixels.js and programmed some custom animations. Felipe Sztutman and GTM Scenography were responsible for putting it all together.

This project was a technical and logistical tour de force. Google gave us the green light for the project mid February of 2017. In April 2017 it was installed and working.

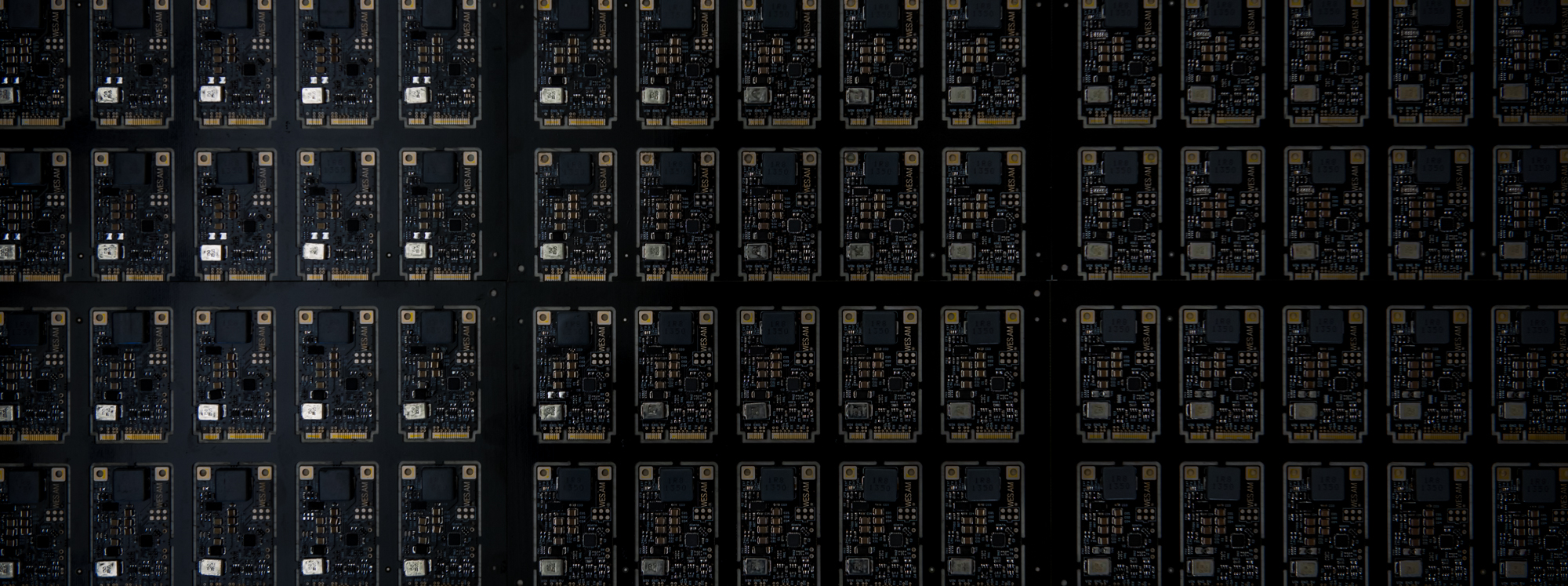

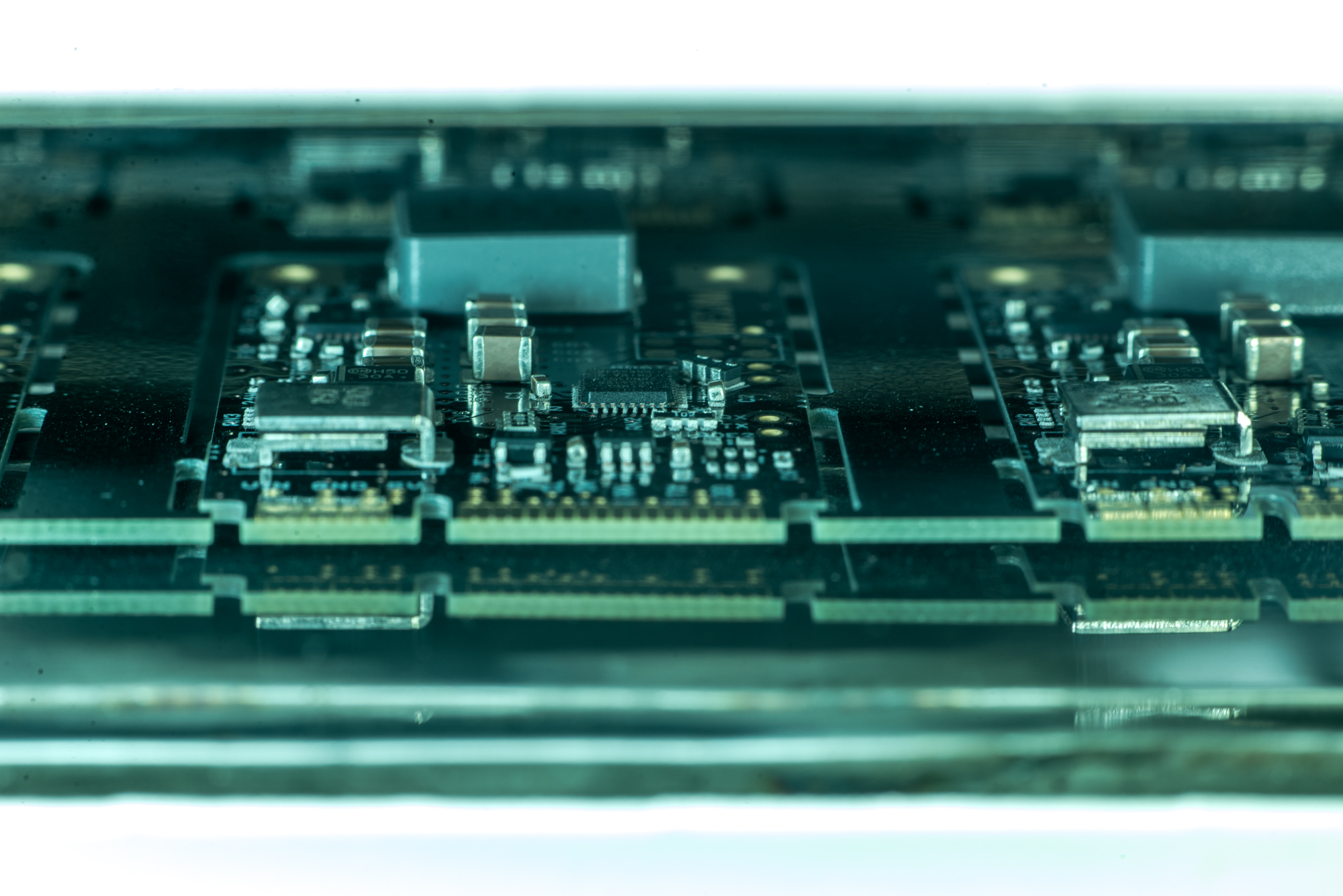

It consists of approx. 7000 RGB backlit buttons, ~150 large PCBs (30k components placed by Fab House), ~150 small controller PCBs (5k hand placed components), ~25 RPis (~25 custom RPi shields), 2 servers and 2 UPS.

In terms of hardware, it required 3 different PCB designs, having hundreds of boards manufactured, some of which were 4 layers, had special thicknesses (1mm) or special size (>300x400mm), all of which required special routing (which aren’t specially complex requirements per se, but considering the schedule and the fact that this was done in Brazil, makes it a bit difficult). The controllers (small black boards) I assembled manually at home (so approx 140 boards * 35 components hand placed), the large boards (LEDs, micro switches, other ICs and passives, connectors and double sided load) were assembled by a fab house. There were also 20+ Raspberry Pis which had a shield with a transceiver, power supply and 3D printed case (also 3D printed and manually assembled by me).

In parallel, components were imported, firmware and software were developed on the interated prototypes, new animations were developed, 7000+ buttons were drilled, metal frames were welded, panels were CNC cut, etc…

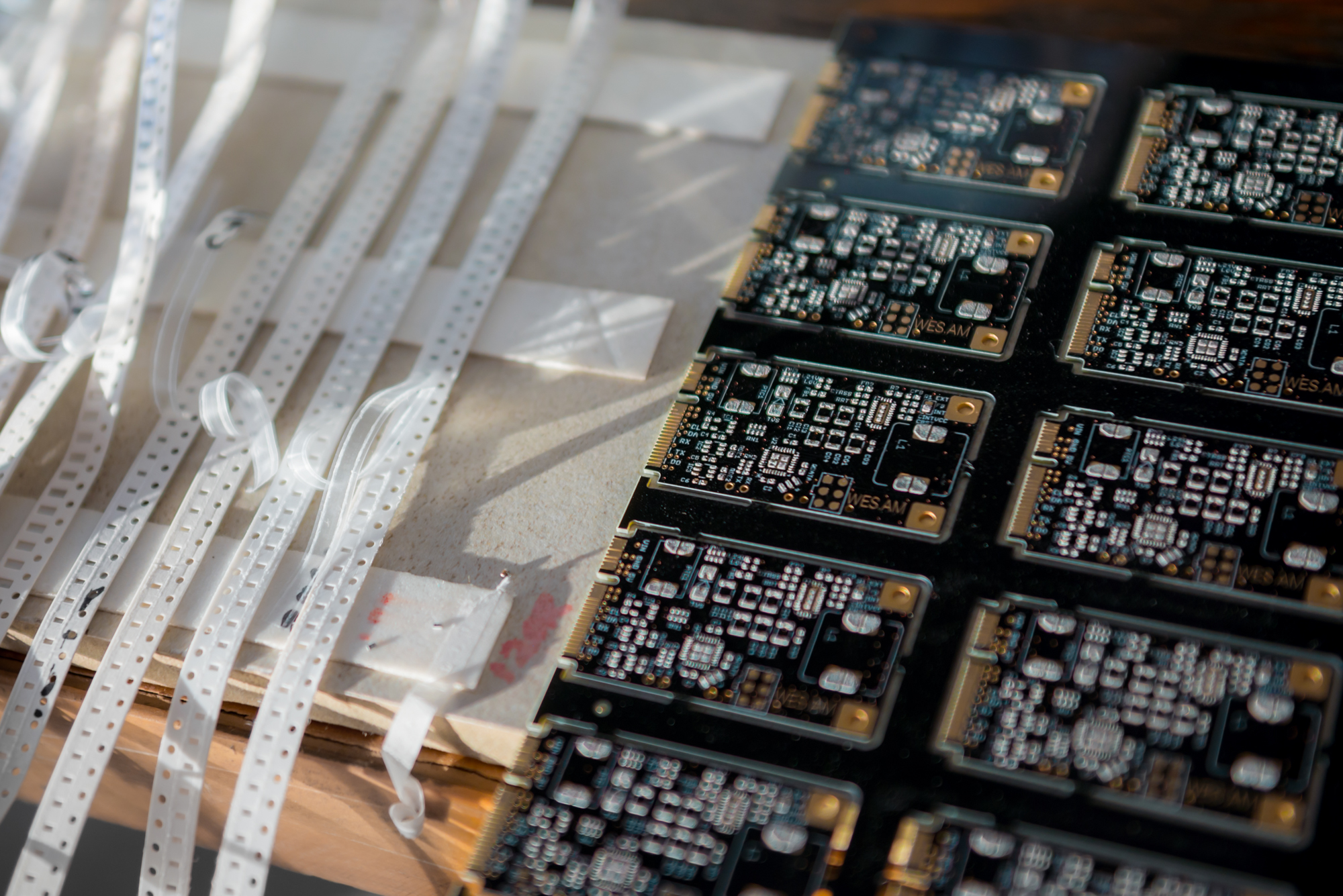

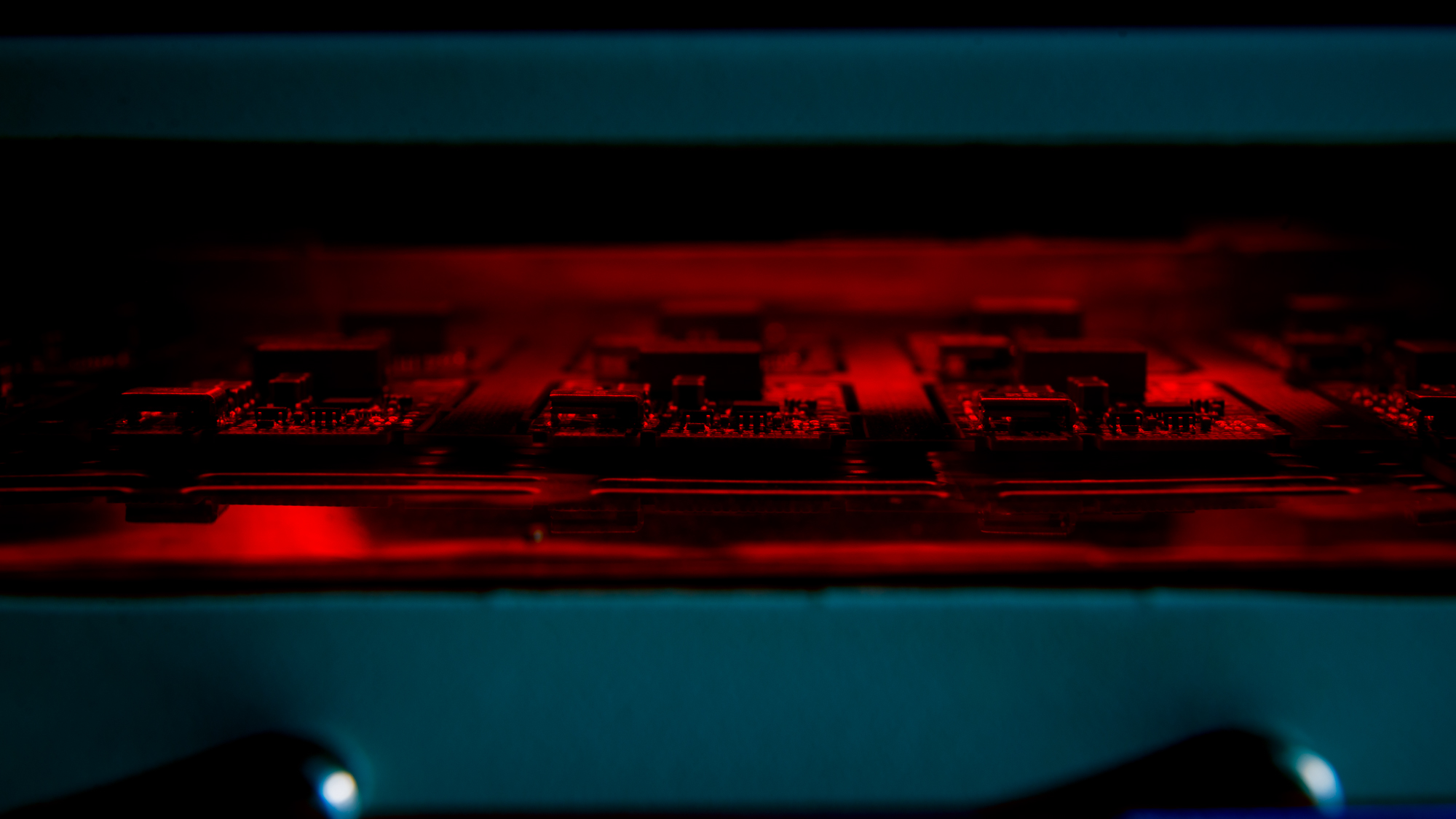

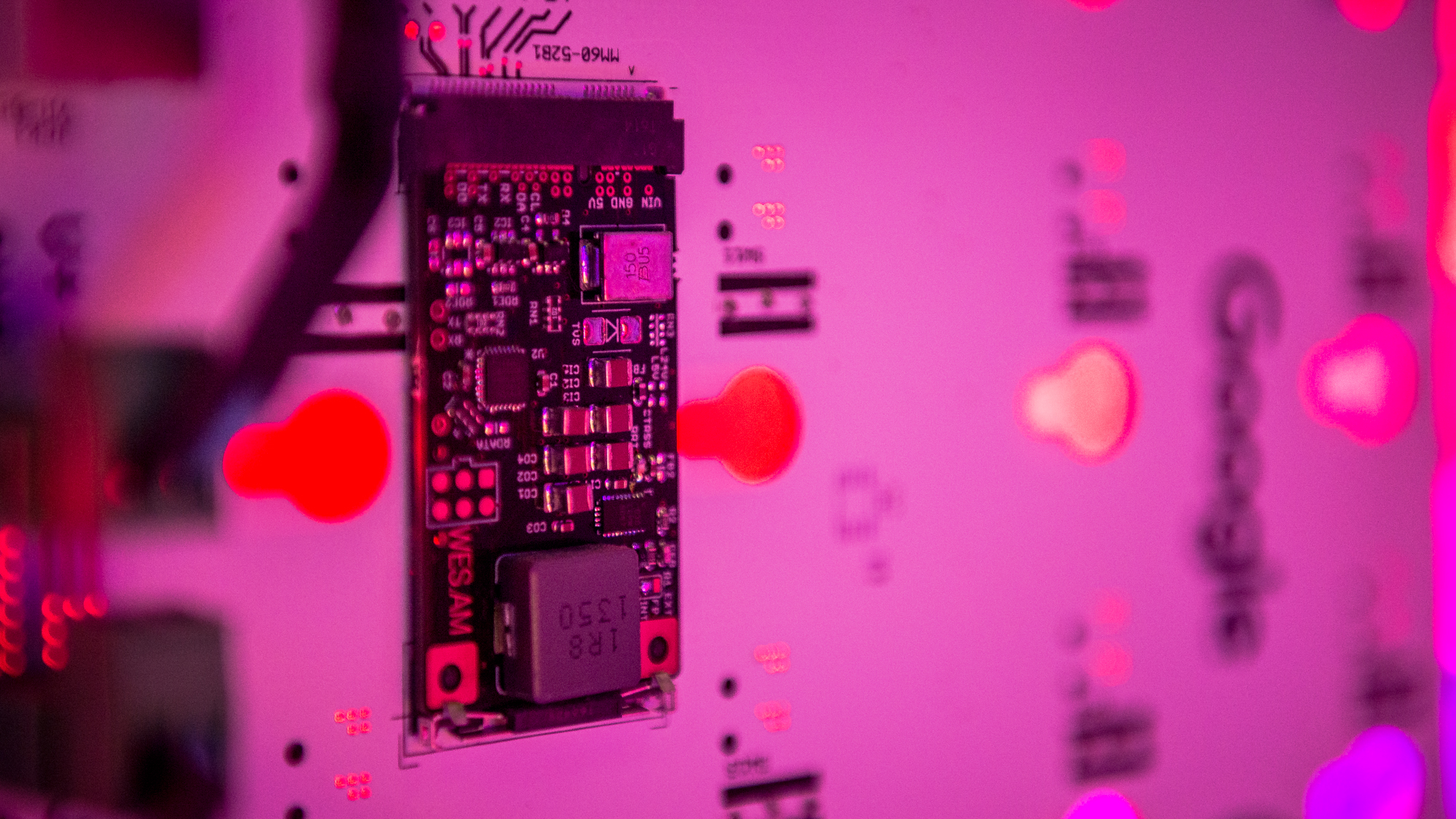

A small making of the controller PCBs at home:

Paste, populate, reflow. Don't rinse, repeat. Assembling PCBs for an installation at Google Sao Paulo in 2017. A few thousands of components hand placed.

Posted by Wesley Lee on Friday, February 23, 2018

Here follows some short clips of the public interacting with it:

A photo of the first prototype, testing switches, LEDs, diffusers, finish, etc:

Playing Tic Tac Toe on the "prototype". This was far from the final version as there are no server or clients, it just runs on an Atmega328/Arduino, but it was important to test colors, power consumption, PCB stiffness, fixing methods, MDF machining tolerances, etc.

Felipe Sztutman checking some of the buttons.

This was built at GTMs factory and then transported to Google Brazil. Only way of finishing in time considering that the building was also under renovations.

Some of the controllers I assembled at home.

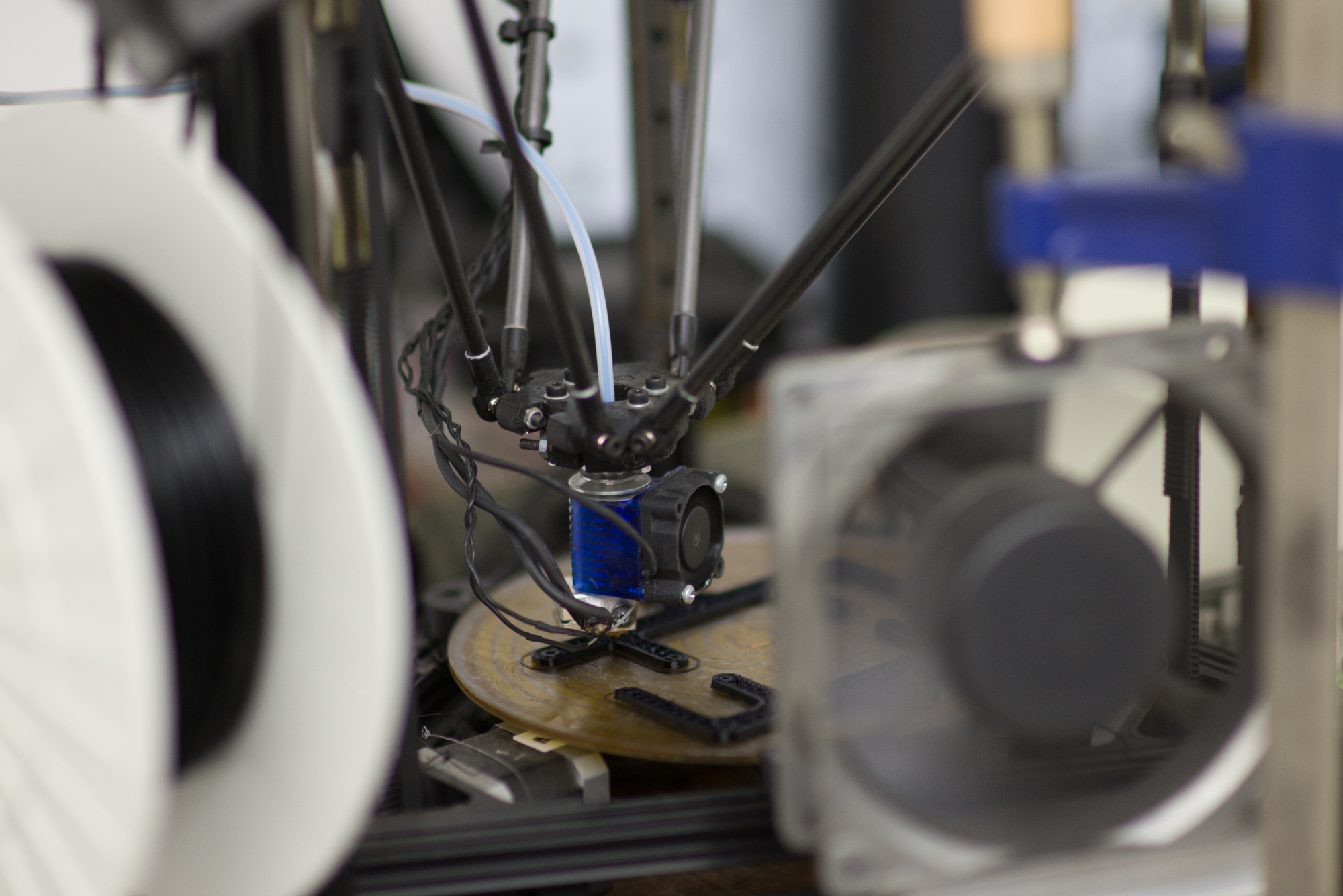

The cases for the RPis 3D printed on my Kossel.

PCBs on a modified chinese reflow oven.

Manual placing setup with vaccum tweezer.